-40%

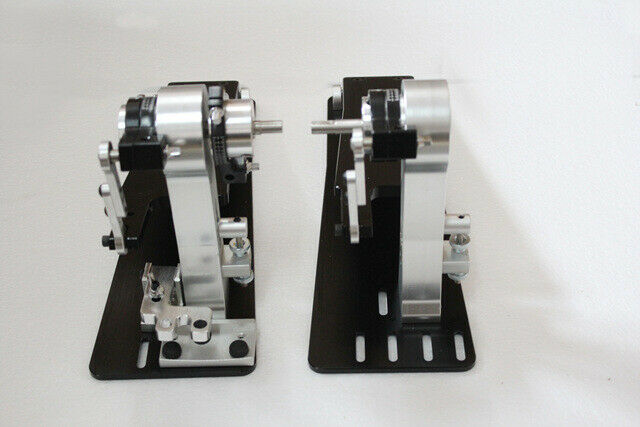

Direct drive 25" Long board double Bass Pedal

$ 192.72

- Description

- Size Guide

Description

Directly Drive 25" Long Board Double Bass PedalIn Black

Material: 7075 aluminum

Made by CNC

Pls review this video via this link: https://youtu.be/YQj1_gPjFKI

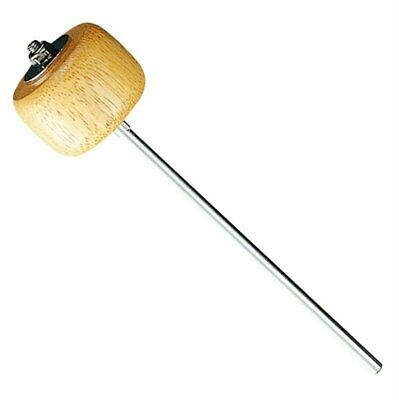

Drum beaters

In standard-made drum pedal the shaft of the beater is made of aluminum with changeable head made of laminate (4) – Picture 1.1. Special key, added to the set, is for changing the heads – Picture

1.2.

The

structure

of

drum

beaters

enables

regulation

of

the

angle

of

drum

beater

head inclination

in

all

planes

because

the

body

(1)

is

mounted

on

ball

bearing

(2)

–

locking

it

on

the required position is executed by unscrewing the screw (3) on the rear part of the body (1) – Picture 1.1. Screw on the end contacting with ball bearing has a cavity with the same diameter as bearing thanks

to

this,

high

fastening

force

can

be

achieved

at

relatively

low

screw

clamping

force.

Both elements – screw and bearing are hardened. It prevents from any wearing of these elements. Drum beater rods are made of extra fine steel and have a standard diameter. So it is possible to use drum beaters from other manufacturers.

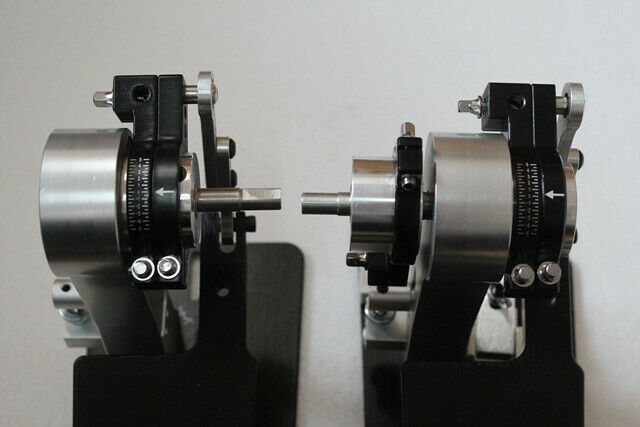

Drum beaters bearing

In

most

constructions

on

the

market,

drum beaters

are

usually

mounted

on

the

axes with bearings and supported on one side. This kind of solution triggers generation of bending forces during pressing

the

pedal by

the

foot.

These forces

are

the

cause

of

majority

of

bearings

damages. Our solution

eliminates

the

adverse

distribution

of

forces.

Every

beater

holder

is

equipped

with

two bearings in a way to apply a load on bearings in the form of only radial forces. It guarantees its long-term and failure-free operation.

Drum beater bearings in main beater

Our construction distinguishes itself

with the symmetric spacing of drum beaters against the bass drum axis what has the significant meaning during the bass drum sound amplification. Thanks to that kind of spacing, the sound from both

drum beaters is identical. The significant condition is well tuned equipment and good drummer. Position of the whole set against the bass drum as dependent on the configuration of clamping arm (1) and central base (2) Picture 1.2.1. in main pedal. It doesn’t matter if its DOUBLE, 2xSINGLE or SINGLE, we always configure it properly. In the situation when we play it alternately – on 2xSINGLE or DOUBLE, and we want our beaters in single pedal to hit exactly the centre of the central and we also want to have a constant symmetric spacing, we would have to configure these elements on our own – description is provided in p. 5.2 Fixing the twin drum pedal – Twin and in p. 5.3 Fixing the single drum pedal – Single

Beater’s angle of inclination adjustment

The beater holder (1) is fixed on the spring holder (2) equipped with bearings and is equipped with a scale cut out on the circuit thanks to which it can be adjusted with high precision. To do that, you have to loosen the tightening screw (3), set the beater holder at the requested angle and tighten the screw again – Picture 1.3.1. The adjustment is carried out really fast and the number of possible combinations is really big – everyone can find his own suitable settings.

Spring tension system

In

most

of

the

drum

pedals

on

the

market

a

spring

adjustment

causes

difficulties,

not mentioning

about

keeping

the

constant

spring

tension

during

a

long

playing

session.

Slackening counter-nuts, adjusting screws deflection during springs operation, creaking, etc. We eliminated all of these problems thanks to the unique construction of the tensioner – Picture 2.1. The whole tensioner construction is patented. Spring tensioner was designed in a way to make the springs adjustment an easy task and, above all, to enable verifying the spring tension in particular situation and what is the most important thing – to make a possibility of reverting to the earlier settings after the adjustment, what often takes place during equipment testing. To do that, the tensioner mechanism was quipped with a scale cut out on a stand and tensioner. Al you need to do is to note the positions suitable to us and revert it every time we want and with full guarantee of repeatability

Spring tension adjustment

To adjust the spring tension all you need to do is to push a tensioner block (1) with your hand – Picture 2.1.1 – the adjusting screw (2) will go down, and you can adjust it from now on. If the block is not forced, no adjustment is possible because the screw is locked with two resisting balls (3) placed under the adjusting screw holder (4). (picture 2.1.1 is pictorial, in reality – the adjusting screw doesn’t have to be lowered so much – situation in which the resisting balls are not placed inside the cavities in adjusting screw, will to the job). After the adjustment and when the pressure is released, screw will go

up

and

lock

in

resisting

balls

–

Picture

2.1.2.

which,

thanks

to

the

spring

tension,

will

fix

the adjusting screw in

the required position.

There are

no counter-screws or any other fixing elements. We guarantee that the spring tension will keep the same level up to the next adjustment.

Replacement of spring

To replace the spring, you have to follow the instructions below – Picture 2.2.1

•

Completely loosen the spring (1) fixed in pedal with the adjusting screw (2)

•

using the 1.5mm Allen wrench, unscrew the screw (3) on the spring suspension (4)

•

dismount the “old” spring

•

suspend the lower hook of the “new” spring on the lower spring slide suspension (5)

•

place the upper hook inside the upper suspension notch (4)

•

screw in the screw again (3)

tension the spring according to p. 2.1 Spring tension adjustment

7

Footboard

Footboard (1) is made of high-quality aluminum and is equipped with an ending (2) used to

join the pedal with the yoke (3). There are four ball bearings – two pieces for each bearing mounting

(4), which is screwed to the base (5) – Picture 3.1. This construction is very resistant to pressure and

bending of the pedal from one side to another, what prevents from clearances so often occurring in

majority

of

constructions

on

the

market.

Picture

below

shows

a

standard

engraving

–

on

Client’s

request we make non-standard designs. To order this, please contact us on our e-mail address.

Yoke – direct drive

Yoke (1) –

Picture

3.1.1 is

equipped

with

two movable

elements joined with each

other by

only one screw (2). Thanks to three holes it is possible to change its length up to 22mm. This kind of

adjustment enables to easily lower the pedal without

any

necessity of changing

any

other settings.

Both ends of the yoke are equipped with bearings.

Pedal’s height adjustment

Pedal’s height is changed by changing the active yoke length (1) Picture 3.1.1. To do this, you

have to unscrew the screw (2) which locks the yoke. Next, put it into the other hole and screw it in

again to achieve

the suitable pedal’s height.

If

the height

doesn’t

suit you, it can be re-adjusted by

adjusting the yoke holder (3). To do this, you have to loosen the screw (4), shift the yoke on spring

holder (5) and tighten the screw (4). You have to remember that in the first method of adjustment,

we

don’t affect

the

operational characteristic of a drum pedal,

but

in the second

method,

we also

change

the

arm length

of the

force

arising

from

the

feet pressure

transmitted

to pedal

–

in

other

words, the bumper striking force is changed.

Change of pedal action

In our drum pedals, we used the

4-grade transmission

adjustment of the

beater movement

against the pedal movement. Thanks to screwing down the screw (1) – Position 3.3.1 into one of the

four holes in yoke holder (2). A

position closest to the

yoke axis of rotation

gives the shorter pedal

shift and fastest beat, and the furthest position trigger the longer pedal shift and higher beating force.

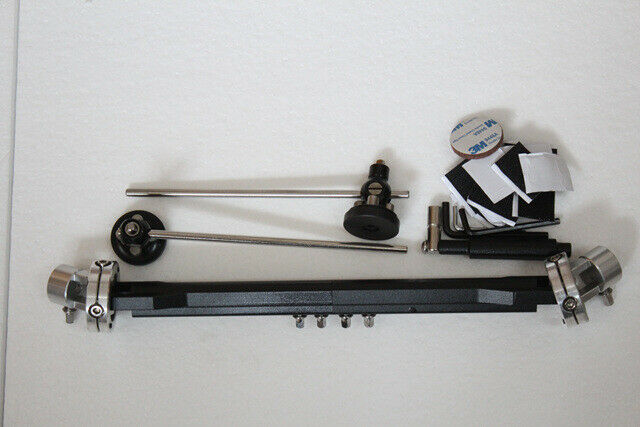

A shaft connecting the main and auxiliary pedals is equipped with cardan joints win which the

torque transmission

is

carried out by

a ring

placed outside the knuckle – circumferentially –

Picture

4.1. All the elements are

made of aluminum

and

every knuckle is

equipped with 2 rolling bearings.

This kind of solution enables to transmit forces larger than in hinges with drive-transmitting element

placed in the middle of the knuckle, and prevents from any clearances during hinge operation.

Both ends of the connecting shaft are ended with cardan joints, which are equipped with set

screws (1) – 2 screw per one joint – Picture 4.1.1, used for fixing it to the main and auxiliary pedal

Connecting shaft length is adjusted by unscrewing two set screws (2), adjusting the shaft to a

suitable length and tightening the screws. Length can be adjusted up to 190 mm against the minimum

length (before unscrewing) – Picture 4.1.2

Attention!!! Care should be taken to set the tightened elements in the correct

position against each other in a way that the ends of two set screws (2) are in contact

with surfaced made on the connecting rod (3).

Connecting shaft installation DOUBLE

To install a connecting shaft in double bass drum pedal, position both pedals – main on the

right and auxiliary on the left side, preferably in parallel. The distance between them should be close

to the required a connecting shaft length. To install the a connecting shaft, insert the pin-stocks (2)

and (3) – Picture 4.2.2 and 4.2.3 of both pedals into the knuckle holes and tighten the four set screws

(1)

Attention!!! Care should be taken to set the tightened elements in the correct

position against each other – Picture 4.2.2 and Picture 4.2.3 in a way that the ends of two

set screws (1) are in contact with surfaced ma

de on pin-stocks (2) and (3)– it is vital for

correct connecting shaft operation and cooperation between main and auxiliary pedals.

If you need the more pictures or video, Pls contact to us

Shipping:

Once payment has been confirmed, your item

will be shipped within 2-3 business days.After the packages are shipped, the seller will provide the tracking number to the buyer. Normally it takes about 3-8days to arrive.

Shippment:

If you can are from South American or other, Pls contact to us . Once payment has been confirmed, your item will be shipped within 2-3 business days.After the packages are shipped, the seller will provide the tracking number to the buyer. Normally it takes about 3-8days to arrive.

Terms of Sale:

If you are not happy with any item, please contact us within 14 days of receipt so that we can arrange for an exchange or refund. After getting the returned item,we will refund the customer at the item’s price.You will pay a 25% restocking fee.

Contact us :

We are always willing to help and if you need any advice pls feel free to email.